Über CNC-Bearbeitung

Apr 11, 2025

Was ist CNC-Bearbeitung?

CNC steht für Computer Numerical Control (Computergestützte numerische Steuerung). CNC-Bearbeitung kann daher als ein Herstellungsprozess definiert werden, bei dem ein Computercode die Parameter des Prozesses steuert, darunter:

Bewegung des Werkzeugmaschinenkopfes.

Bewegung des Teils bzw. Vorschub.

Drehzahl.

Werkzeugauswahl für Multitoolköpfe.

Kühlmittelmenge, falls erforderlich.

Einfach ausgedrückt bedeutet dies, dass alle notwendigen Bewegungen einer Maschine zur Herstellung von Teilen aus Rohmaterial mithilfe von Rechenleistung gesteuert und überwacht werden.

Wie funktioniert CNC-Bearbeitung?

Grundsätzlich stellt das CNC-Programm Befehle bereit, die die Maschine lesen und verstehen kann. Diese Befehle teilen den Motoren der Maschine mit, wann und wie sie die entsprechenden Komponenten bewegen sollen, um die gewünschten Ergebnisse zu erzielen.

Die ersten CNC-Maschinen verwendeten Lochkarten mit geschriebenem Code und hatten eine eingeschränkte Flexibilität bei der Bewegung des Werkzeugs.

Moderne CNC-Maschinen können jedoch mit CAD/CAM-Software (Computer Aided Design/Computer Aided Manufacturing) verbunden werden. Das bedeutet, dass der Konstrukteur ein 3D-Modell des Teils erstellen und die Parameter des Teils anschließend mithilfe der CAM-Software in ein CNC-Programm übertragen kann.

Dieses von der CAM-Software erstellte endgültige Programm wird in die Maschine eingespeist, und der Fertigungsprozess beginnt. Das Teil ist fertig, sobald die Maschine das Programm ausgeführt hat.

Ein weiterer wichtiger Aspekt der aktuellen und modernsten CNC-Maschinen ist ihre Flexibilität, da sie sich je nach Maschinentyp in einem Bereich von 2,5, 3 oder 5 Achsen bewegen können.

CNC-Bearbeitung für HolzWährend viele denken, dass Holzbearbeitung eine Kunst ist, die nur den geschicktesten Schnitzern vorbehalten ist, ermöglicht die CNC-Holzbearbeitung in Wahrheit effizienteres Arbeiten. Selbst bei den komplexesten Designs.

Mit CNC-Holzbearbeitung können größere Teile in kürzerer Zeit hergestellt werden. Außerdem kann der Holzarbeiter die natürliche Schönheit und Festigkeit des verwendeten Holzes bewahren, was mit anderen Holzbearbeitungsmaschinen nur schwer zu erreichen ist.

Weitere Vorteile der CNC-Bearbeitung von Holz sind:

Komplexe Formen, die für die manuelle Arbeit zu schwierig sind, können problemlos erreicht werden.

Höhere Präzision und kürzere Produktionszeiten.

Höhere Effizienz und weniger Materialabfall.

Erhöhte Rentabilität.

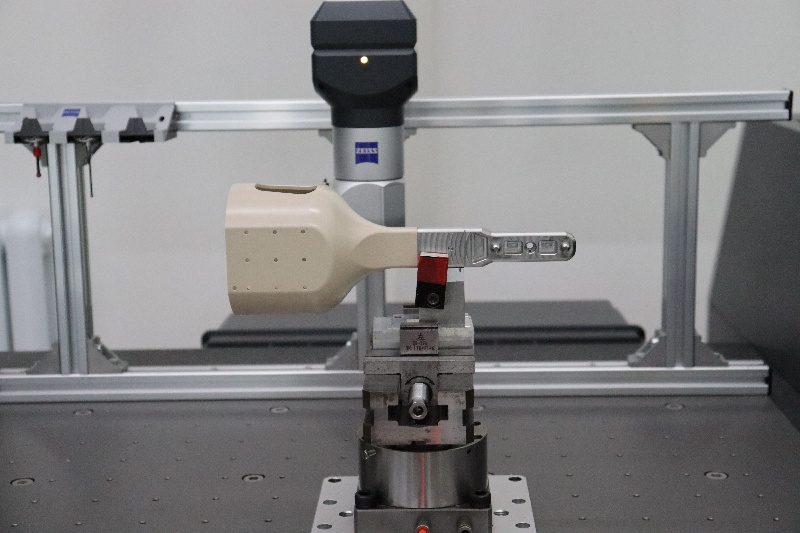

CNC-Bearbeitung für die MedizinindustrieEs ist bekannt, dass die Medizinbranche sehr anspruchsvoll ist und viele Standards erfüllt werden müssen. Dies gilt auch für die CNC-Bearbeitung in der Medizinbranche.

Glücklicherweise liegen die Hauptvorteile der CNC-Bearbeitung, wie bereits erwähnt, in der hohen Effizienz und Genauigkeit, die fast keinen Raum für Fehler lassen.

Dies macht die CNC-Bearbeitung für die Medizinbranche zur besten Fertigungsoption in der Branche. Präzisionsbearbeitung ist die bevorzugte Alternative, um die engen Toleranzanforderungen zu erfüllen. Weitere gängige Anforderungen sind:

Komplexe Geometrien, die normalerweise 5-Achsen-Maschinen erfordern.

Sehr hohe Sauberkeitsstandards.

Möglichkeit der Bearbeitung verschiedener Sondermaterialien.

Oberflächenfinish auf höchstem Niveau.

Zu den gängigen Anwendungen der CNC-Bearbeitung in der Medizinbranche gehören:

Implantate und Prothetik.

Chirurgische Instrumente.

Elektronische Komponenten für medizinische Geräte.

Mikromedizinische Geräte, die Mikrobearbeitung erfordern.

CNC-Bearbeitung für GussteileGießen ist ein Herstellungsverfahren, das für die Erzielung der gewünschten Ergebnisse auf gute Formen angewiesen ist. Daher ist es notwendig, das optimale Verfahren zur Herstellung der Formen auszuwählen.

Die CNC-Bearbeitung von Gussteilen auf 5-Achs-Maschinen reduziert das Fehlerrisiko, das durch das Bewegen des Gussteils zwischen den Bearbeitungsvorgängen entsteht. Diese Fehlerreduzierung ermöglicht es, engste Toleranzen für das Gussteil einzuhalten.

Ein weiterer Vorteil der CNC-Bearbeitung für Gussteile liegt darin, dass die meisten Gussteile eine Nachbearbeitung zur Verbesserung der Oberflächengüte benötigen. Mit der CNC-Bearbeitung für Gussteile lässt sich die gewünschte Oberflächengüte schnell und effizient erzielen.

Darüber hinaus kann die CNC-Bearbeitung mit den Arten von Materialien umgehen, die üblicherweise für Gussteile verwendet werden, wie z. B. Aluminium, was ein Problem für andere Fertigungsprobleme darstellen kann.

CNC-Bearbeitung für Aluminium

Aluminium ist ein Leichtmetall und wird für viele Anwendungen bevorzugt, insbesondere in der Automobil- und Luftfahrtindustrie. Allerdings erfordert der Einsatz in einigen dieser Anwendungen sehr komplexe Formen.

Darüber hinaus können dünne Teile erforderlich sein, was aufgrund der geringen Härte und der hohen Wärmeausdehnung des Materials die Möglichkeit einer Verformung erhöht.

Hier kommt der CNC-Bearbeitung von Aluminium eine wichtige Bedeutung zu. Die 5-Achsen-CNC-Bearbeitung von Aluminium bietet folgende Vorteile:

Die Einrichtung ist einfach, was die Vorlaufzeiten verkürzt und die Effizienz verbessert

Es ermöglicht die Arbeit mit komplexer Geometrie, da beim Neigen des Wok-Tisches oder des Schneidwerkzeugs eine Kollision mit dem Werkzeughalter vermieden wird.

Es können kürzere und steifere Werkzeuge verwendet werden, einige mit hohen Spindeldrehzahlen, was durch die Reduzierung der Belastung des Schneidwerkzeugs erreicht wird.

Die Teile müssen nicht durch verschiedene Arbeitsstationen gehen, wodurch die Fehler reduziert, die Genauigkeit erhöht und die Qualität sichergestellt wird.

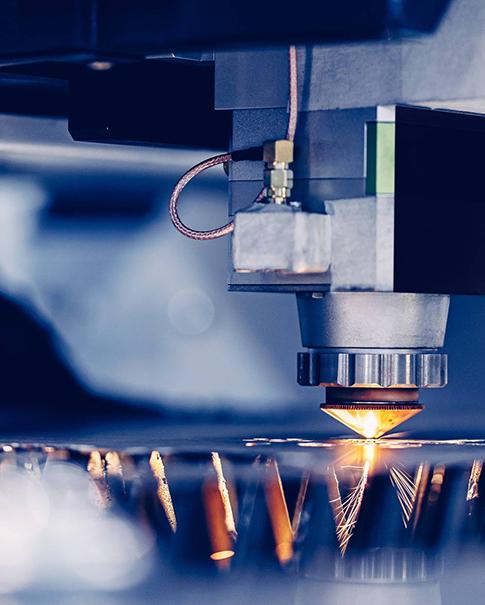

Diese Maschinen können andere Alternativen wie Wasserstrahlschneiden oder Laserschneiden verwenden, wodurch die Probleme bei der Arbeit mit sehr dünnen Aluminiumteilen vermieden werden.

CNC-Bearbeitung für Luft- und Raumfahrtteile

Angesichts der Anzahl und Komplexität der für die Montage eines Flugzeugs erforderlichen Komponenten ist es klar, dass die Luft- und Raumfahrtindustrie von einem Herstellungsprozess die höchstmögliche Präzision und Effizienz verlangt.

Aus diesem Grund erfreut sich die CNC-Bearbeitung von Teilen für die Luft- und Raumfahrt zunehmender Beliebtheit und ist heute die bevorzugte Option für die Herstellung von Komponenten für die Luft- und Raumfahrt.

Die CNC-Bearbeitung von Teilen für die Luft- und Raumfahrt muss komplexe Anforderungen erfüllen, wie beispielsweise:

Arbeiten mit dünnen Wänden.

Begrenzung der Materialverformung, beispielsweise bei der Verarbeitung von Aluminium und anderen Leichtbauwerkstoffen.

Arbeiten mit gekrümmten und komplexen Geometrien.

Andererseits ist die CNC-Bearbeitung die beste Option für die Produktion von Teilen für die Luft- und Raumfahrt, da sie die folgenden Vorteile bietet:

Es ist ein kostengünstiger Prozess.

Es kann qualitativ hochwertige Ergebnisse liefern.

Es kann mit benutzerdefinierten Designs arbeiten.

Es bietet hohe Genauigkeit und Präzisionstechnik.

Es reduziert und eliminiert manchmal menschliche Fehler.

Es können komplexe Geometrien erzeugt werden.

CNC-Bearbeitung für Schmuck

Früher wurde Schmuck ausschließlich von Kunsthandwerkern in Handarbeit gefertigt. Dies ist heute jedoch nicht mehr der Fall, da immer mehr Schmuckhersteller Methoden zur Verbesserung ihrer Effizienz und Steigerung ihrer Rentabilität einsetzen.

Die CNC-Bearbeitung für Schmuck bietet Handwerkern und Schmuckherstellern vielfältige Vorteile. Die häufigsten Vorteile sind:

Erstellen Sie ganz einfach Mastermodelle zum Gießen der Juwelen.

Erstellen Sie schnell und mit hoher Genauigkeit Gussformen.

Erstellen Sie edle Schmuckstücke für den Endverbraucher mithilfe hochentwickelter CNC-Maschinen.

Erstellen Sie schnell und präzise individuelle Gravuren.

Einfache Veredelung der Juwelen durch Marmorfacetten- und Juwelenpolierverfahren.

CNC-Bearbeitungstoleranzen

Zwar hat die CNC-Bearbeitung die Fertigungsgenauigkeit auf ein sehr hohes Niveau gebracht. Doch wie bei anderen Fertigungsverfahren sind die Abmessungen des Endprodukts nie perfekt. Und hier spielen die CNC-Bearbeitungstoleranzen eine wichtige Rolle.

Wir müssen bedenken, dass Toleranzen die maximal zulässige Abweichung für die gleichen Abmessungen zweier Teile aus der gleichen Serie darstellen. Sie werden normalerweise in der Entwurfsphase festgelegt.

Bei der Festlegung der erforderlichen Toleranzen sind verschiedene Aspekte zu berücksichtigen:

Passende Komponenten.

Art der Materialien.

Verfügbare Herstellungsverfahren.

Engere Toleranzen sind in der Regel teurer zu erreichen.

Toleranzen werden üblicherweise nach ihrer Enge in folgende Gruppen eingeteilt:

Feine Toleranzen.

Mittlere Toleranzen.

Grobe Toleranzen.

Sehr grobe Toleranzen.

Im Allgemeinen werden die Grenzwerte für jede Gruppe auf Grundlage internationaler Normen festgelegt, darunter ANSI B4.1, ANSI B4.2, ISO 286, ISO 1829, ISO 2768, EN 20286 und JIS B 0401.

Die Toleranzen für die CNC-Bearbeitung liegen standardmäßig im Bereich von ± 0,005 Zoll bzw. 0,13 mm. Einige sehr anspruchsvolle Dienstleister behaupten jedoch, CNC-Bearbeitungstoleranzen von bis zu ± 0,0025 mm anbieten zu können.

Hier sind einige Standardtoleranzen für die CNC-Bearbeitung, abhängig vom CNC-Prozess:

Drehbank – ±0,005″ (0,13 mm)

Fräser – ± 0,005″ (0,13 mm)

3-Achsen-Fräsen – ± 0,005″ (0,13 mm)

5-Achsen-Fräsen – ± 0,005″ (0,13 mm)

Gravur — ± 0,005″ (0,13 mm)

Ebenheit – ± 0,010″ (0,25 mm)

ABONNIEREN SIE UNSEREN NEWSLETTER

ABONNIEREN SIE UNSEREN NEWSLETTER